Discover what’s next for AI in healthcare in 2026 - Get Access to the Full Report

Top Technology Benefits We Deliver

Real-Time Data Visibility

Collect, consolidate, analyze, and present operational data derived from multiple plant sources. Using standardized protocols, our manufacturing systems enable accurate aggregation of signals from machinery, sensors, and software applications.

Clients benefit from timely analytical data and detailed reports needed to support informed managerial responses to production variances.

Automated Process Optimization

Implement continuous, automated analysis of sequence patterns and resource allocation within production workflows.

The applied methodology measurably improves process consistency. Supplementary monitoring helps manufacturing firms identify bottlenecks and make adjustments with verifiable results in both output and expenditure.

Enterprise System Integration

We integrate MES, ERP (SAP, Oracle), PLM, and supply chain systems. Our software architecture supports bi-directional data exchange secured with standardized APIs and compliance protocols.

With this optimal level of connectivity, manufacturing firms can reduce administrative overhead with centralized control in procurement, production, logistics, and quality assurance layers.

Advanced QA & Traceability

Our software systems support forward and backward traceability at all the critical stages of production. Automated checkpoints and traceability mechanisms generate comprehensive provenance records for both internal reviews and regulatory audits.

Hence, manufacturers can isolate production issues and maintain product lineage records from raw material intake to final dispatch.

Custom Software Solutions We Offer for Manufacturers

Manufacturing Execution System (MES)

Our MES solutions provide full visibility and control of plant-floor workflows. Capture accurate quality data and coordinate operational activities to address long-term production demands.

Enterprise Resource Planning (ERP) Software

Through AI-driven analytics, user role controls, and system integration, we provide centralized platforms that generate actionable intelligence and unify all aspects of business management.

Supply Chain Management Software

Our SCM solutions provide visibility and control to suppliers through integrating logistics, demand forecasting, real-time analytics, risk management, and performance tracking.

Order & Inventory Management Systems

Digitize stock management for raw materials, WIP, and finished goods. Leverage predictive restocking, automated cycle counts, and digital order capture to reduce processing time.

Product Lifecycle Management Solutions

We build PLM tools to manage product data, automate documentation and collaboration, and help teams adhere to quality targets across design-to-manufacture workflows.

Warehouse & Equipment Management System

Our manufacturing software developers architect systems with smart picking algorithms and robotic integrations to maximize shipping/storage efficiency and reduce labor costs.

BPA & Workflow Optimization

Let us help you automate repetitive processes. We map current business processes, integrate automation protocols, and deliver workflow builders tailored to your organization.

Quality Management System

Digital quality systems we build are integrated with barcode scanners and digital records to provide a unified platform for supplier-to-customer traceability and electronic documentation.

Industrial IoT (IIoT) Application Development

Connect physical and digital systems for actionable intelligence. We build IoT-enabled monitoring, maintenance, and data-driven control for all asset classes on the plant floor.

Artificial Intelligence & Machine Learning

We integrate AI and ML models by ingesting historical and real-time production data to build and automate quality inspections and predictive maintenance schedules.

- Predictive maintenance cuts unplanned downtime

- Vision tools automate inspection on 100% of output

- Real-time anomaly alerts improve response times

- ML forecasts demand to reduce excess stock

IIoT & Edge Computing

IoT sensors and edge devices are integral in software development for manufacturing. These technologies collect and preprocess data as close to the source as possible.

- Edge devices provide visibility of equipment status

- Local processing supports sub-second fault detection

- Securely links legacy machines with modern networks

- Increases asset utilization by centralizing monitoring

Cloud Platforms & Infrastructure

Our cloud experts help manufacturers move MES to the cloud native architecture. Reduce deployment times by up to 40% and achieve centralized control across plants.

- Build multi-tenant cloud apps with segmented access

- Automate CI/CD pipelines for rapid software releases

- Provide virtualized environments for diverse apps

- Ensure data backups and disaster recovery mechanisms

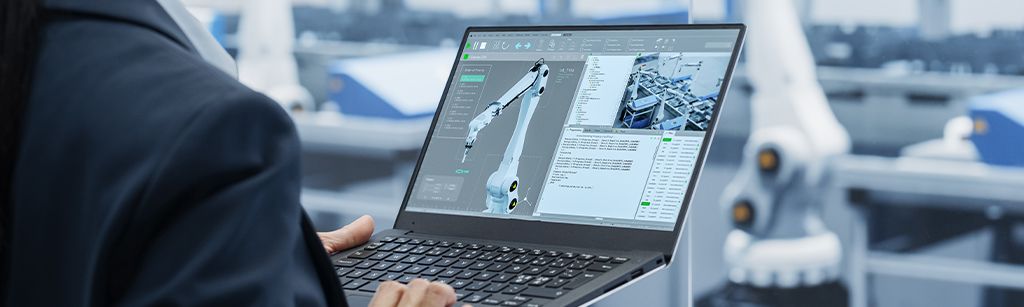

Automation & Robotics

Automation engineers at Radixweb implement RPA solutions by programming software and robots to execute scheduled tasks with high accuracy and reliability.

- Automate manual data entry and routine workflows

- Develop robot programs for repetitive or hazardous tasks

- Configure cobots to support operator activities safely

- Integrate AGVs with plant floor control systems

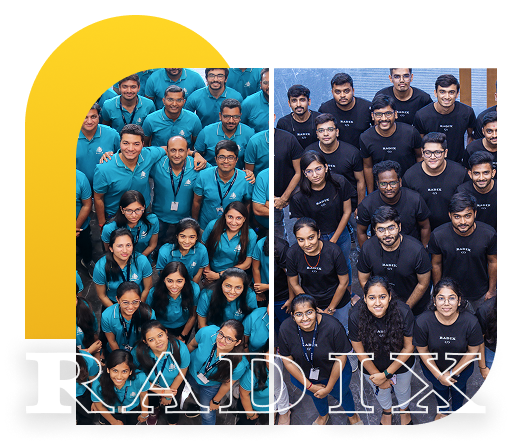

About Radixweb

Projects, Partnerships, and Performance Metrics in Digital Engineering

Radixweb has worked with 3000+ global enterprises across asset-heavy, high-throughput industries. As a manufacturing software development company, our specialization includes full-cycle digital transformation, factory automation, and enterprise intelligence.

Custom Software Projects Successfully Delivered

Client Satisfaction Score over 5 Years

Full-Time Engineers and Consultants

Developer Rating on Clutch and G2

Our Extended Scope of Manufacturing Solutions

Asset Management Systems

We integrate sensor networks and ML models to monitor asset conditions, advise optimized maintenance schedules, and reduce unplanned machinery downtime.

Human-Machine Interface (HMI) Software

Design intuitive HMI panels with customizable dashboards. By connecting operator stations to live plant controls, we deliver visual insights with interactive status display.

Process Optimization with AI

Developers at Radixweb have extensive experience in building AI-driven solutions that you can use to analyze production data and adjust process parameters automatically.

Digital Twin Solutions

We develop digital twin frameworks replicating physical equipment. These virtual models support performance simulation, anomaly prediction, and scenario testing.

Connected Worker Platforms

The best manufacturing software systems offer shop-floor personnel with mobile access to instructions, safety protocols, and incident reporting. We can help you build the same.

OT Cybersecurity Tools

Our custom software development solutions include multi-tiered security layers like network segmentation and automated incident response to safeguard your manufacturing assets.

Regulatory Compliance Software

Configurable modules we create automate routine audits, document control, and reporting to help manufacturers comply with sector-specific regulations and customer mandates.

KPI & Analytics Dashboards

Enable fact-based decisions at every organizational level. Our teams design manufacturing software with role-based visualization for trend analysis and targeted insights.

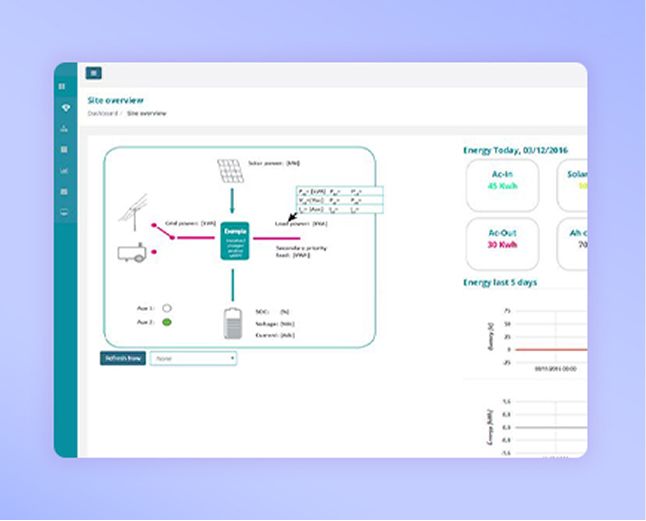

Energy Monitoring Systems

We deploy metering and IoT connectivity to track energy consumption across production assets. Dashboards highlight inefficiencies and usage patterns for sustainability targets.

Reimagine Your Manufacturing Business. Talk to Our Industry 4.0 Consultants and Engineers.

Our Engagements with Manufacturers

Tools and Technologies in Our Practice

- Emerging Tech

- Frontend

- Backend

- Mobile

- Database

- Frameworks

- Cloud

- DevOps

- Platforms

- Analytics

Industry Awards and Client Endorsements

The focus is always on creating a usable solution that we are happy with rather than ticking boxes to say they have done what was in the brief/spec.

The team of Radixweb has deliberately helped us save a lot of time and resources by not giving us a single chance of having to hire a full-time developer.

They’re maintaining the platform to the best of their capabilities despite the infrastructure that was set up previously. Radixweb is making the best of what they have.

Everything we have today is thanks to what they’ve built. We’re going to enter another phase with them to make the product available on the cloud.

It gives us this sense of pride when our customers say that they are flattered by the UI/UX. We know we chose the right people in the way they have made our solution unique.

The time zone differences have never become an issue with Radixweb. When in need, they work more than six days in a week and even late to deliver the required solutions.

Reasons to Select Us for Your Manufacturing Software Project

A technically intensive domain, manufacturing is one of our technically demanding focus areas, covering process automation, MES, cloud integration, and connected systems.

- Industry 4.0 Product Consultation and Engineering

- ISO 27001 and 9001 Certified Security and QA Practices

- GMP and IATF 16949-Compliant Development Expertise

- AWS and Microsoft Solutions Partner for Innovation

Frequently Asked Questions

What are manufacturing software development services, and why are they critical for modern factories?

What does a manufacturing software development company do?

Which types of manufacturing do you support - discrete, process, or hybrid?

Can you modernize our existing legacy systems or on-prem MES/ERP?

How do you ensure software meets manufacturing compliance standards like GMP or IATF 16949?

What is your experience with IIoT and smart factory systems?

How long does it take to build custom manufacturing software?

What makes your team different from other software vendors?

See how we’d approach your challenges. Get clarity on scope, tech stack, and next steps.