Discover what’s next for AI in healthcare in 2026 - Get Access to the Full Report

The manufacturing industry, like every other industry, is under pressure to deliver faster while still maintaining quality and constantly optimizing costs. Once an operational challenge, it quickly becomes a boardroom priority when the bottom line starts to waver.

Our client, a mid-sized manufacturer with multiple plants in the Midwest, was struggling with the same.

Over the last decade, their business grew and so did the number of platforms they used. The problem? The systems, which were originally supposed boost productivity, had started to cause operational inefficiencies. How? Due to multiple ERP and shop-floor systems that didn’t integrate or interact with one another. These disconnected systems caused:

- Slower business operations

- 20–25% IT cost increase over prior years

- Limited visibility across the organization

- Reduced production flexibility

- Higher risk of errors and compliance issues

PowerApps enterprise solutions emerged as a way to address these challenges. With Microsoft PowerApps for enterprises, we helped them connect existing systems, reduce manual work, and offered real-time visibility across systems.

Did You Know? A Forrester survey found that PowerApps integration services can help save ~250 hours/year. That's more than 6 weeks of productive time, per employee, per year.

The Ultimate Goal: Manufacturing IT Cost Reduction with PowerApps

Our client knew that they needed more than just a software upgrade to bring about manufacturing IT cost reductions. They wanted a complete transformation of how their plants operated. For that, we started by understanding their key business goals. Then as a part of our PowerApps consulting services we conducted workshops with plant managers, IT teams, and operations leaders. This helped align the technical solutions with their needs.

Based on the deep dives the key technical goals which had to be achieved were:

- Consolidate data from legacy ERPs, systems & spreadsheets into a central repository

- Use a low-code or no-code development platform to build custom apps for inventory, supplier onboarding, and maintenance

- Integration between legacy systems, new apps & microservices with middleware/APIs

- Build infrastructure for reporting & dashboards on production, inventory & compliance

- Centralize role-based authentication and access management

- High-performance design to handle multiple plants and large transaction volumes

- Tools for data cleaning, deduplication, and governance

Next, we did a thorough technical audit of their existing systems. This helped identify hidden dependencies, data inconsistencies, and user adoption challenges that would arise during custom enterprise application development.

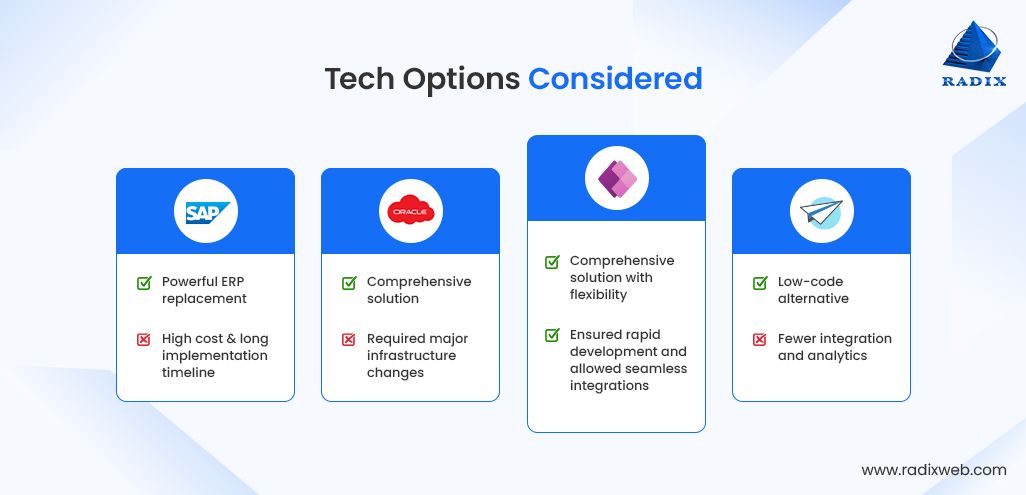

Why We Chose Power Apps

Our client needed a platform that could unify systems, enable innovation, and support integrations. To deliver such a 360-degree solution, we evaluated several tech options.

The high PowerApps ROI for enterprises was the main reason we chose it for this project. Here’s why it stood out:

- With Power Apps’ low-code enterprise solutions, we could build plant-specific apps in weeks not months.

- Since Power Apps connects natively with Microsoft 365, Azure, and our ERP, it felt like an extension of what they already had.

- Suitability of Power Apps for modernizing manufacturing made it easy to start small and then scale across plants.

Important: To ensure PowerApps was viable for this project we also used the PowerApps assessment checklist.

Supporting Technologies

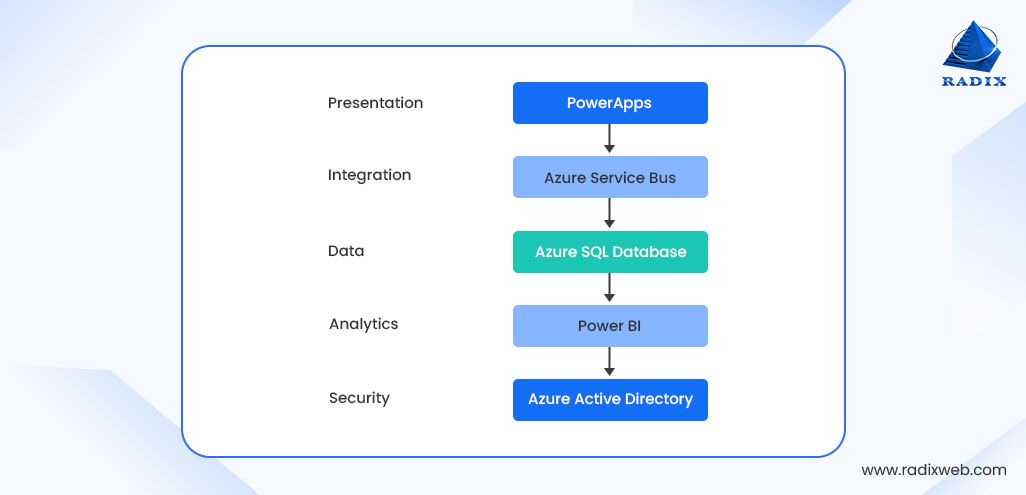

Along with the PowerApps for cost reduction strategy, we also used the following technologies to complete the stack:

- Azure SQL Database for centralized data storage

- Azure Service Bus as the middleware for real-time communication between legacy systems and new apps.

- .NET Core Microservices as the business logic for production scheduling and inventory processing.

- Power BI for real-time dashboards to monitor production, inventory, and compliance metrics.

- Azure Active Directory for centralized role-based authentication and access management across all systems.

Here is a simplified system architecture diagram of our proposed legacy app modernization with PowerApps

With this setup of Power Apps for manufacturing operation, we aimed to set up a robust, scalable, and secure system for our client.

From Blueprint to Execution: How We Used Custom PowerApps Development to Bring Down Costs

Once the consulting phase defined the roadmap and the technology stack was finalized, we moved into solutioning and turned the strategy into execution.

Below, we’ve explained our solutioning approach to using Power Apps for manufacturing along with core challenges that we faced in each step and how we tackled those.

Step 1: Unified Data Model Design

The client’s data was fragmented across ERPs, Excel sheets, and custom exports. Each plant had its own version of ‘truth.’ Before any modernization could succeed, we had to design a unified data model that standardized core entities such as inventory, suppliers, and production orders, creating the foundation for reliable analytics and system-wide consistency

| Challenge | Solution |

|---|---|

| Legacy systems stored the same information in different structures. Details were in Excel at one site, a flat-file ERP export at another plant. | We used Azure Data Factory to build ETL pipelines that normalized data formats and performed cleansing, deduplication, and validation. This ensured reporting and analytics weren’t corrupted by inconsistent inputs. |

Step 2: Integration Layer Development

Real-time communication was mission-critical. Shop-floor scheduling, supplier updates, and inventory changes had to sync instantly across plants. But the client’s legacy systems lacked APIs, making system-to-system communication unreliable. We built an integration layer to serve as the backbone of orchestration. This enabled secure, real-time data flow without replacing legacy assets

| Challenge | Solution |

|---|---|

| Some legacy systems were built 15+ years ago and had no APIs | We wrapped the legacy processes inside .NET Core microservices that exposed modern REST APIs and gave old systems “new life.” This solved the real-time integration gap and also avoided the high cost of ripping out older systems. |

Step 3: Custom PowerApps Development

Once the data and integration layers were stable, the next challenge was usability. Operators and managers needed tools that matched their workflows, not abstract dashboards. We delivered three modular Power Apps for manufacturing that could be quickly adopted by frontline users:

- Inventory Tracker provided unified stock visibility across warehouses, reducing reliance on paper logs.

- Supplier Portal digitized supplier interactions, cutting email back-and-forth and lost documentation.

- Maintenance Manager automated scheduling and tracked downtime trends, improving equipment uptime.

| Challenge | Resolution |

|---|---|

| Shop floors often lacked stable Internet | Leveraging PowerApps’ offline sync features, we built local caching that let users continue work offline and push changes when connectivity returned. |

Step 4: Workflow Automation

Digitization solved visibility gaps, but people were still spending hours on repetitive approvals, compliance checks, and supplier updates. To truly unlock efficiency, workflows had to be automated, not just digitized. We introduced automation that embedded business rules directly into processes, eliminating bottlenecks while maintaining compliance

| Challenge | Solution |

|---|---|

| Some workflows overlapped, leading to duplicate approvals and even “looped” triggers where one action retriggered itself. | To solve this, we built a custom rule engine within the .NET Core layer that validated workflow triggers against business logic before allowing execution. |

Step 5: Analytics Layer

Leaders at our client’s organization had long relied on static weekly reports, often outdated by the time they reached the boardroom. The new platform had to deliver live, role-specific insights. For that, we built an analytics layer on Power BI that transformed reporting from reactive to real-time decision-making.

| Challenge | Solution |

|---|---|

| Early versions overwhelmed users with 20+ KPIs per dashboard. | Through role-specific workshops, we came down to only 5–7 KPIs per role. Plant managers saw operational KPIs like downtime and output; CFOs saw cost savings and supplier efficiency. |

Step 6: Security & Compliance

With plants spread across multiple regions and compliance standards, security was non-negotiable. The client needed role-based access that matched a global security baseline. We built a governance model that combined Azure AD authentication with conditional access policies, balancing usability with enterprise-grade protection.

| Challenge | Resolution |

|---|---|

| Plants across different regions operated under varying compliance requirements | By using conditional access policies, we allowed local flexibility while enforcing a consistent global security baseline. This dual approach struck the right balance between governance and usability. |

Step 7: Pilot & Scale-Up

Rolling out a platform across multiple plants at once was too risky. User resistance, legacy dependencies, and adoption hurdles could derail the initiative. We launched a pilot Power Apps manufacturing integration at one mid-sized plant with 300 employees. We used this rollout as a controlled environment to refine the apps, address resistance, and build momentum before scaling to all sites.

| Challenge | Solution |

|---|---|

| Resistance to change was real as many floor managers insisted Excel was “good enough.” | Instead of forcing migration, we embedded Excel import/export functionality in the early app versions. Over time, as managers saw the benefits of live dashboards and automated alerts, reliance on Excel naturally reduced. |

Final Build Outcomes: Calculating the PowerApps ROI for Enterprises

After the project, the final outcomes of our Power Apps for manufacturing operation project were:

- Unified 5 fragmented platforms into 1 integrated enterprise application

- Developed custom apps for mission-critical workflows, tightly integrated with existing systems.

- Better scalability and security with cloud-native architecture and ERP integration with Power Apps

- Managed change resistance by blending old tools with new until adoption stabilized.

Especially with Power Apps integration, we were able to ensure the right balance of rapid deployment, integration capability, scalability, and enterprise-grade security for the client’s application modernization goals.

Driving Results That Mattered with Microsoft PowerApps

Despite the bumps along the way, the use of Power Apps for modernizing manufacturing operations delivered measurable impact:

- Consolidation of five legacy apps helped reduce IT costs with PowerApps development by 30% annually.

- Supplier onboarding dropped from 2 weeks to 8 days.

- Real-time visibility reduced overstock and stockouts, resulting in a 20% reducing in working capital that was blocked due to inventory holding

- Compliance reports generated in hours instead of weeks, with full audit trails.

- Leadership gained real-time KPIs for production, inventory, and supplier performance.

- Maintenance staff could schedule and log tasks digitally, reducing manual paperwork by ~35%.