Read More

Discover what’s next for AI in healthcare in 2026 - Get Access to the Full Report

ON THIS PAGE

- What is AI in Manufacturing

- How AI in Manufacturing Has Evolved Over the Years

- Benefits of Using Artificial Intelligence in Manufacturing Industry

- How AI is Being Used in Manufacturing – Use Cases and Examples

- Challenges of Using AI in Manufacturing

- Implementing AI in Manufacturing – A Step-by-Step Blueprint

- Future Outlook of AI in Manufacturing

ON THIS PAGE

- What is AI in Manufacturing

- How AI in Manufacturing Has Evolved Over the Years

- Benefits of Using Artificial Intelligence in Manufacturing Industry

- How AI is Being Used in Manufacturing – Use Cases and Examples

- Challenges of Using AI in Manufacturing

- Implementing AI in Manufacturing – A Step-by-Step Blueprint

- Future Outlook of AI in Manufacturing

Summary: According to a National Association of Manufacturers (NAM) survey, 72% of organizations reported cost savings and efficiency enhancements after using Artificial Intelligence in the manufacturing industry. This isn't a one-off instance. Numerous industry reports suggest the same. AI-powered manufacturing solutions are revolutionizing the industry. Or are they? An MIT study revealed that AI projects have a 95% failure rate. So how do you ensure success with AI implementation? In this blog, we dive into the what, why, how of using AI in manufacturing. The complete guide is right here.

Project deployment is only one part of the story.

Most organizations see little to no benefits from the use of AI in manufacturing projects. AI promises to revolutionize manufacturing. Cutting downtime, boosting productivity, and streamlining supply chains. But AI statistics show that 80% of initiatives fail to move beyond pilot projects.

This is because of the J-curve of productivity. In manufacturing, AI rarely delivers instant results. Early initiatives often show limited or uneven gains. This makes projects feel underwhelming and leads to premature skepticism.

But with the right strategy and support, the initial slow climb gives way to rapid improvements. Benefits are seen in efficiency, predictive maintenance, quality control, and supply chain optimization. How? We'll cover all that and more about what AI in manufacturing automation truly involves in this blog right here. The goal is to help you take the first steps confidently and avoid the pitfalls that hinder results.

What is AI in Manufacturing?

In the simplest terms, AI in manufacturing refers to the use of smart software to look at data, find useful insights, and help make better decisions. Unlike traditional automation, (which follows fixed instructions) AI learns from real-time data and adjusts itself. Such AI applications in manufacturing help companies go from reactive to proactive problem solving.

AI integrates with machines, sensors, and enterprise systems to deliver actionable intelligence. Common implementations include:

- Predictive analytics for machinery and process maintenance, reducing downtime before failures occur.

- Computer vision for quality control, identifying defects faster and more accurately.

- Digital twins, which simulate production environments to model and test changes before implementation.

- Natural language processing, analyzing maintenance logs, operator reports, or production notes to uncover inefficiencies or emerging issues.

The real impact of AI-powered manufacturing software development is not just efficiency. AI improves product quality, reduces waste, and creates a foundation for continuous improvement. Companies that integrate AI thoughtfully see measurable results in operational performance and decision-making agility.

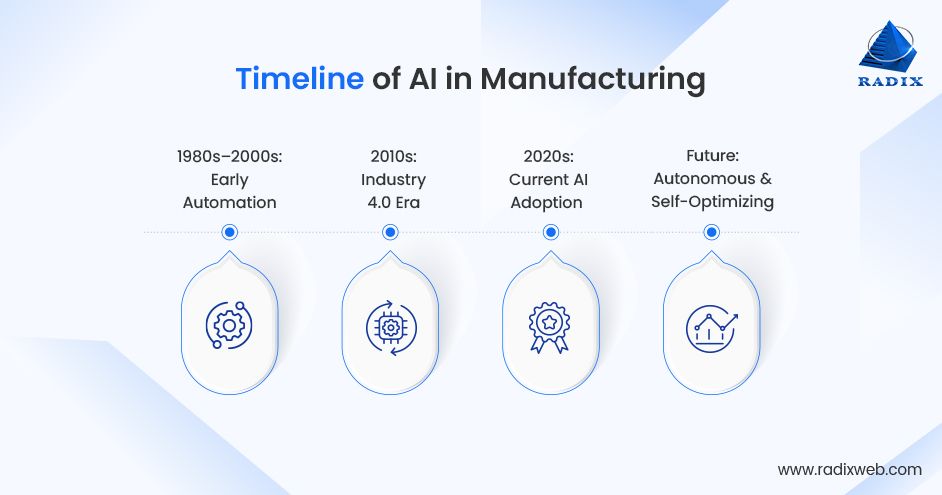

How AI in Manufacturing has Evolved Over the Years

AI for manufacturing isn't a 2025-concept. Instead, manufacturing has been one of the earliest adopters of artificial intelligence. Over the decades, there has been a gradual move from basic automation to advanced operations.

Here's how the evolution has panned out:

Early Automation (1980s–2000s)

- Manufacturing relied on fixed rules and programmable logic controllers.

- Machines followed strict instructions, performing repetitive tasks consistently.

- It improved reliability but processes lacked adaptability.

- Human oversight was still essential for decision-making.

Industry 4.0 Era (2010s)

- The proliferation of IoT devices, sensors, and connected machinery created volumes of ops data during the Industry 4.0 era.

- Early AI applications in manufacturing focused on analyzing this data to identify inefficiencies, predict equipment failures, and improve process visibility.

- Adoption remained uneven due to integration challenges and limited analytics capabilities.

The Current State of AI in Manufacturing

- Today, AI in manufacturing automation leverages advanced ML models, computer vision, and analytics.

- Systems can predict failures, optimize production schedules, and adjust operations dynamically.

- Large manufacturers are using AI to monitor entire factories in real time. Mid-market manufacturers are gradually integrating AI into ERP and MES systems. This is being termed as Industry 5.0 for manufacturing.

Future of AI in Manufacturing

- The next stage includes autonomous production lines, generative design, and self-optimizing supply chains.

- AI models will simulate complex scenarios and recommend actionable changes.

- This will help manufacturers respond instantly to market shifts or operational anomalies.

The evolution shows that AI for manufacturing is no longer optional. Companies that wait risk falling behind competitors who use AI to improve efficiency, reduce costs, and enhance decision-making. Leaders who understand the progression and the current capabilities of AI are better equipped to plan realistic implementation strategies.

Benefits of AI in Manufacturing

The tangible advantages of using AI in manufacturing are becoming increasingly clear. From operational efficiency to strategic decision-making, AI is transforming the way factories operate.

Operational Efficiency

Predictive maintenance and AI-driven process optimization reduce unplanned downtime by 30–50 percent, keeping production schedules on track and maximizing equipment utilization.

Quality Control

AI-powered computer vision and analytics detect defects that human inspectors might miss, reducing scrap rates and improving product consistency. Leading manufacturers report defect reductions of up to 90 percent when these systems are properly implemented.

Supply Chain Optimization

AI improves forecasting accuracy, minimizes inventory costs, and prevents stockouts. Companies using AI for supply chain decisions often achieve 20–50 percent improvements in planning efficiency.

Energy Optimization

AI models can analyze energy consumption patterns and suggest adjustments in real time, resulting in cost savings of 10–20 percent and contributing to sustainability goals.

Workforce Augmentation

By automating repetitive monitoring and analysis tasks, AI frees human operators to focus on higher-value activities, such as process improvement and decision-making. Upskilling the workforce to work alongside AI ensures long-term adaptability and organizational resilience.

In our experience, these benefits of AI in manufacturing are most pronounced when AI is integrated into existing systems and processes, rather than applied in isolation. Leaders who align AI-powered manufacturing solutions with operational goals see measurable returns within months, not years.

Also Read: Complete Guide to Manufacturing Software Development

How AI is Being Used in Manufacturing – Use Cases and Examples

Understanding AI use cases, especially in industries like manufacturing, is critical for leaders evaluating investments. The most value is attained when AI is used in high-impact areas where data is available and measurable outcomes can be tracked.

Here are the most significant use cases and real-world examples:

Predictive Maintenance

Predictive maintenance uses AI to monitor equipment health and forecast failures. GE Aviation, for example, applies AI to monitor turbines, predicting issues before they cause downtime. This approach reduces maintenance costs and prevents unplanned production halts.

Quality Control and Defect Detection

AI-powered computer vision identifies defects in products faster and more accurately than human inspection. BMW uses AI systems to inspect car surfaces, catching imperfections invisible to the human eye. When integrated with production workflows, this reduces scrap rates and improves consistency across batches.

Supply Chain and Demand Forecasting

Companies like Unilever leverage AI to anticipate raw material needs and optimize inventory. AI forecasts allow for proactive adjustments, minimizing stockouts and excess inventory. From a software standpoint, AI models ingest data from ERP, procurement, and sales systems to deliver actionable recommendations in near real time.

Energy Management

Energy costs are significant for manufacturers. Siemens employs AI to monitor energy consumption across facilities, adjusting operations dynamically to reduce waste and lower costs. Such AI-based energy optimizations can improve efficiency by 10–20 percent within the first deployment cycle.

Production Scheduling and Process Optimization

Tesla uses AI-driven scheduling algorithms to allocate resources efficiently across assembly lines, minimizing bottlenecks and improving throughput. This level of dynamic scheduling requires deep integration with MES and ERP systems, ensuring that insights translate into actionable production adjustments.

These examples illustrate how AI applications in manufacturing deliver measurable outcomes. Leaders should prioritize initiatives that align with operational goals, have accessible data, and produce clear KPIs. By focusing on high-impact use cases first, organizations can build momentum and scale AI adoption effectively.

Challenges of Using AI in Manufacturing

While the benefits are clear, the challenges of using Artificial Intelligence in the manufacturing industry are equally significant. Awareness of these obstacles is crucial for CIOs and technology leaders who want to implement AI successfully.

Data Quality and Accessibility

Many manufacturers struggle with siloed or unstructured data. Without clean, reliable data, AI models fail to produce accurate predictions. Dedicated data audit is the first step toward meaningful AI deployment.

System Integration

AI must connect seamlessly with ERP, MES, and SCADA systems. Poor integration reduces the value of insights and can create workflow disruptions. Experienced vendors, however, can help you design architectures that bridge these systems effectively.

Cost and ROI Concerns

AI initiatives require investment in software, cloud infrastructure, and specialized talent. Defining KPIs and aligning them with measurable operational improvements helps justify the expenditure.

Talent Shortages

Skilled AI engineers, data scientists, and system integrators are scarce. Partnering with experienced vendors like Radixweb fills this gap and accelerates implementation.

Cybersecurity and Compliance

Connected systems increase exposure to cyber threats. AI solutions must include robust access controls, data encryption, and regulatory compliance measures.

Resistance to Change

Operators and engineers may hesitate to trust AI recommendations. Involving teams early, training staff, and demonstrating clear benefits helps drive adoption.

Addressing these manufacturing industry challenges requires a structured approach, strong vendor collaboration, and a focus on tangible results. From my experience, organizations that anticipate these obstacles and plan mitigation strategies achieve higher success rates and faster ROI.

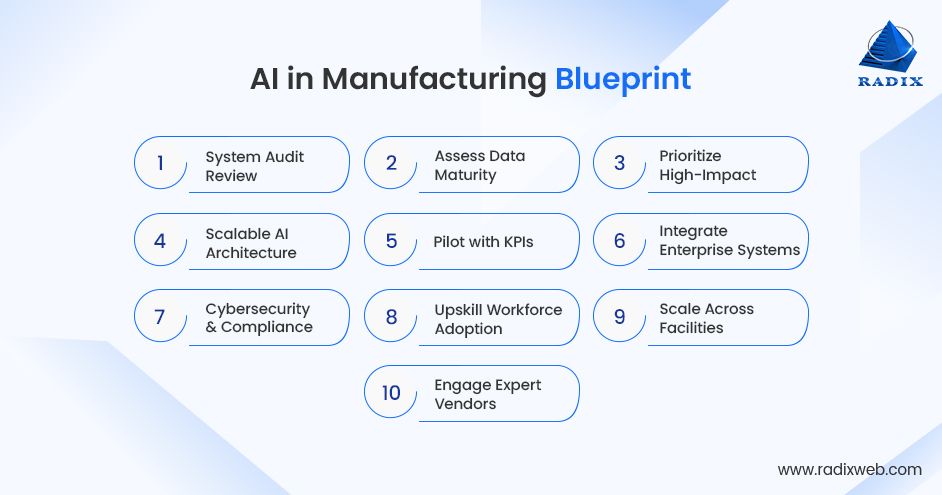

Implementing AI in Manufacturing – A Step-by-Step Blueprint

From our years of experience delivering AI solutions for manufacturers of various scales across geographies, we have seen that projects succeed when they follow a structured, practical roadmap rather than an abstract plan. Here is a step-by-step blueprint that you can follow:

1. Conduct a Comprehensive System Audit

Evaluate existing ERP, MES, and IoT infrastructure. Identify integration points and legacy constraints. Understanding the current environment helps avoid costly redesigns later.

2. Assess Data Maturity

Inventory all available operational data. Clean and standardize historical records and establish robust pipelines for real-time data collection. High-quality data is the foundation for effective AI in manufacturing automation.

3. Prioritize High-Impact Use Cases

Select use cases that deliver measurable business outcomes, such as predictive maintenance, quality inspection, or energy optimization. Start with areas where ROI can be tracked quickly.

4. Design Scalable AI Architecture

Implement a cloud-native framework with edge computing where necessary. Ensure AI models are modular and adaptable to future production changes.

5. Pilot Projects with Clear KPIs

Deploy AI in a controlled environment, monitoring defined metrics such as downtime reduction, defect rate, and energy efficiency. Early pilots help validate assumptions and refine models.

6. Integrate AI with Enterprise Systems

Connect AI outputs to ERP, MES, and SCADA systems. Automation of actionable insights ensures AI recommendations translate into operational improvements.

7. Establish Cybersecurity and Compliance Measures

Implement access controls, data encryption, and regulatory compliance frameworks. This safeguards AI systems and builds trust across the organization.

8. Upskill Workforce and Encourage Adoption

Train operators and engineers to understand AI outputs. Foster a culture where AI assists decision-making rather than replaces human judgment.

9. Scale Across Facilities

Expand AI applications beyond the pilot, adjusting models and workflows for different plants or production lines. Continuous monitoring ensures KPIs remain aligned with operational goals.

10. Engage Expert Vendors for Ongoing Support

Partnering with experienced teams like Radixweb ensures models remain accurate, systems stay integrated, and AI evolves with operational needs. Long-term support prevents pilot fatigue and accelerates full-scale adoption.

Following this blueprint allows AI projects to deliver measurable outcomes rather than remaining theoretical. Leaders who adhere to these steps mitigate common pitfalls such as data gaps, integration challenges, and poor adoption rates.

Getting Started with AI in ManufacturingNow is the right time to begin AI adoption. Early projects allow teams to develop the necessary data infrastructure, integrate systems, and upskill the workforce while demonstrating tangible results. By working with experts with practical experience and technical expertise, you can ensure that you move beyond experimentation to scalable, repeatable AI success.Leaders who act today position their organizations to reap long-term operational, financial, and strategic benefits, while those who delay risk falling behind competitors already enabling AI applications in manufacturing.If you are ready to make the best use of AI for your manufacturing business, schedule a strategy session with our experts at Radixweb. With technical AI expertise and a deep understanding of the manufacturing business, we are ready to help you drive smart manufacturing outcomes with AI.

FAQs

What is the ROI of AI in manufacturing and how long before results show?

Is AI adoption feasible for mid-sized manufacturers or only enterprises?

How can AI reduce costs in manufacturing?

What are the biggest risks of AI in manufacturing and how to mitigate them?

How do I choose the right AI partner for manufacturing solutions?

How can I scale AI from a pilot to enterprise-wide adoption?

Ready to brush up on something new? We've got more to read right this way.