Read More

Discover what’s next for AI in healthcare in 2026 - Get Access to the Full Report

ON THIS PAGE

- Introduction to AI in Automotive Industry

- AI in Automotive Industry: The Evolution

- AI in Automotive Industry: Most Popular Use Cases

- AI in Automotive Industry: Benefits for Companies

- AI in Automotive Industry: Key Challenges

- AI in Automotive Industry: Implementation Roadmap

- Getting Started with AI in Automotive Industry

ON THIS PAGE

- Introduction to AI in Automotive Industry

- AI in Automotive Industry: The Evolution

- AI in Automotive Industry: Most Popular Use Cases

- AI in Automotive Industry: Benefits for Companies

- AI in Automotive Industry: Key Challenges

- AI in Automotive Industry: Implementation Roadmap

- Getting Started with AI in Automotive Industry

Summary: Artificial intelligence in the automotive industry is redefining how vehicles are designed, built, and experienced. From intelligent manufacturing to autonomous driving, AI solutions are accelerating innovation, improving safety, and enabling sustainable mobility. This article explains how AI is driving the next era of connected and intelligent transportation.

The global automotive landscape is undergoing one of the most transformative periods. Electrification, connected vehicles, sustainability goals, and a growing customer demand for personalization are all redefining every aspect of the automotive sector. Automakers, today, are navigating complex challenges too. There are supply chain disruptions, evolving safety standards, and stringent environmental regulations.

And at the center of this revolution sits Artificial Intelligence - driving smarter decisions, predictive insights, and intelligent automation.

But the use of AI in the automotive industry extends far beyond basic automation. Instead, it integrates deep learning, computer vision, predictive analytics, and AI agent development too. The result is vehicles and manufacturing systems that are able to learn, adapt and optimize continuously.

This evolution signals a move from automation to intelligence.

At Radixweb, we have guided several automotive enterprises and helped them power through in this new era of mobility. In this blog, we share our insights, based on years of experience, so that you stay ahead of the AI transformation curve.

What is AI in Automotive?

AI in automotive refers to the integration of intelligent tech like machine learning, computer vision, natural language processing (NLP), and predictive analytics within the automotive value chain. From concept design and production to vehicle maintenance and customer experiences, the use of AI in the automotive industry is creating a smarter, safer, and more connected ecosystem.

At its core, AI enables vehicles and systems to process vast amounts of data and make real-time decisions. Manufacturers, for example, leverage AI technology in the automotive industry to optimize design efficiency, predict maintenance needs, and deliver adaptive drive assistance. Similarly, in-vehicle AI is used to enhance user experience with voice recognition, gesture control, and personalized infotainment systems.

The application of AI in the automotive industry can be best understood as a digital co-pilot supporting both automakers and drivers.

How has the Use of AI in the Automotive Industry Evolved Over the Years?

Over the past two decades, the use of AI in the automotive industry has moved from supporting processes to enabling predictive, data-driven decision making. Here is how it has evolved:

Early 2000s – Basic Automation Era

- Adoption of robotic assembly lines for consistent quality and efficiency.

- Introduction of electronic control units (ECUs) for real-time system monitoring.

- Early diagnostics tools that support predictive fault detection.

- Streamlined manufacturing processes with programmable automation

2010–2015 – Connected Vehicles and Data Era

- Integration of telematics and connected sensors to gather vehicle data

- Emergence of cloud-based data analytics to improve performance monitoring

- Infotainment systems powered by intelligent interfaces and driver insights

- Early examples of AI use cases included remote diagnostics and predictive maintenance

2016–2020 – Intelligent Systems Emergence

- Widespread adoption of driver-assistance systems and adaptive cruise control

- Introduction of predictive maintenance and AI-based quality inspection

- Personalized in-car experiences through AI-driven infotainment systems

- Noticeable impact of AI in the automotive industry on safety and customer experience

2021–Present – Autonomous and Predictive Era

- Rapid adoption of ADAS and semi-autonomous driving technologies

- AI integration in R&D for simulation and design optimization

- Predictive analytics improving supply chain and fleet management

- Growing focus on energy optimization and sustainable AI-driven mobility

Future Outlook – The Next Frontier of Mobility

- Full autonomy and intelligent traffic coordination for urban mobility

- AI-powered sustainability through optimized EV battery management

- Integration of vehicles into smart city infrastructure

- Expansion of application of AI in the automotive industry to mobility-as-a-service and predictive ecosystems

As we move towards a more autonomous future, the impact of AI on the automotive industry will only continue to grow. It is expected to empower manufacturers, mobility innovators, and customers with safer, cleaner, and more efficient solutions tailored for the transportation and logistics industry.

What are the Popular Use Cases of AI in the Automotive Industry?

The real strength of AI in the automotive industry lies in the way it enhances safety, efficiency, and UX across every layer in the value chain. Modern vehicles and manufacturing systems have now become intelligent, data-driven ecosystems, which learn, adapt, and improve with real-world feedback.

Below are some of the most transformative AI use cases in the automotive industry, which show how intelligence is shaping the next era of mobility.

| AI Use Case | How is it being used in Automotive? |

|---|---|

| 1. Autonomous Driving | AI enables vehicles to perceive their environment (via cameras, lidar, radar, GPS), make driving decisions (lane-keeping, obstacle avoidance, braking/steering) and control movement autonomously or semi-autonomously. |

| Waymo’s autonomous vehicles use AI to process data from cameras, lidar, and radar, enabling them to safely drive themselves by detecting obstacles and making real-time driving decisions with no human intervention. Waymo operates commercial driverless taxi services in select cities like Phoenix. Read more here. | |

| 2. AI Vehicle Design | Generative and predictive AI systems are used in early vehicle development to generate novel design proposals, iterate rapidly, balance engineering and aesthetics, and compress the time from concept to prototype. |

| Toyota Research Institute uses generative AI to help designers quickly generate and refine vehicle concepts. Their AI tool converts text prompts like “sleek” or “SUV-like” into prototype sketches, balancing aesthetics with engineering needs and speeding up the initial design-to-prototype phase. Read more here. | |

| 3. V2X Connectivity | AI analyses data from vehicles, infrastructure, and external sensors to enable communication between vehicles (V2V), infrastructure (V2I), and everything else (V2X) in order to optimize traffic flow, safety, route planning, and cooperative control. |

| Audi has deployed AI-powered V2X connectivity through its Traffic Light Information system, which uses vehicle and infrastructure data to optimize driving routes and enhance safety. The system communicates with traffic signals, allowing cars to adjust speed and route based on live signal data, improving traffic flow, and reducing stop-and-go driving. Read more here. | |

| 4. Emotion Recognition | AI uses computer vision, voice analysis and biometric sensors to detect the driver’s emotional or cognitive state (stress, fatigue, anger etc.) and the car dynamically adjusts parameters (lighting, music, control sensitivity) to improve comfort and safety. |

| Affectiva Automotive AI uses AI-powered computer vision and biometric sensors to monitor a driver’s emotional state, such as stress or fatigue, and adjusts car settings like lighting and music to improve comfort and safety. Read more here. | |

| 5. AI 3D Printing | AI analyses CAD models, material/structural constraints and printing parameters to optimize part geometry, weight, production speed and waste, enabling custom or low-volume parts via additive manufacturing (3D printing). |

| BMW uses AI to optimize 3D printing of lightweight metal components that reduce vehicle weight while maintaining strength. They’ve produced more than 300,000 3D-printed parts in 2023 alone, including for their electric vehicles. Read more here. | |

| 6. Cyberthreat Detection | AI monitors vehicle networks, sensors and software systems in real time; it detects anomalies, learns behavioral patterns of normal operation and identifies unusual signals/intrusions, then triggers countermeasures to isolate threats and protect vehicle systems. |

| Securyzr™ IDS employs AI models to detect sophisticated cyber threats with high accuracy, adapts through over-the-air updates, and integrates edge and cloud computing for robust vehicle security. Read more here. | |

| 7. Dynamic Pricing | AI systems analyze market data (inventory, competitor prices, consumer behavior, demand signals) to adjust vehicle retail pricing dynamically and personalize offers, optimizing profitability, turnover and competitive positioning. |

| CarMax uses AI-driven dynamic pricing systems to analyze market data and competitor prices in real time, optimizing vehicle retail prices to maximize profitability and turnover. This approach allows personalized offers and effective stock management to stay competitive. Read more here. | |

| 8. Smart Manufacturing | AI orchestrates robotic systems, machine vision, sensor data and production processes in automotive factories, enabling adaptive manufacturing, real-time adjustments, quality control, and improved throughput, improving quality and reducing rework. |

| Tesla’s use of AI-powered vision systems on their production lines to inspect parts and vehicles for defects such as surface imperfections and assembly errors. Tesla’s AI systems provide rapid, automated quality checks that help maintain manufacturing standards and reduce costly errors. Read more here. | |

| 9. EV Battery Management | With electric vehicle software development, AI analyses sensor data from battery cells (temperature, charge history, usage patterns) to predict degradation, optimize charging/discharging cycles and power distribution, improving battery lifespan, range accuracy and efficiency. |

| Electra Vehicles offers an AI-powered battery management system called EVE-Ai 360 Adaptive Controls. It uses real-time sensor data and predictive algorithms to optimize charging, predict degradation, and extend battery life. Read more here. | |

| 10. In-Car Personalization | AI uses driver behavior, vehicle trip data, external context (location, time, journey purpose) and infotainment usage to deliver contextual advertisements, service offers or suggestions inside the vehicle, tailored to the individual. |

| NIO, the electric vehicle manufacturer, uses AI for in-car personalization through its NOMI AI system. NOMI learns driver preferences, monitors driving habits, and adapts the cabin environment, infotainment, and even conversational responses to enhance the user experience. Read more here. | |

| 11. AI Supply Chain | AI analyses supply-chain data (supplier performance, logistics, weather, market trends, geopolitical events) to forecast disruptions, manage inventory, optimize vendor operations and improve risk resilience in the automotive supply chain. |

| General Motors (GM) uses AI to map tier-one and sub-tier suppliers, monitoring supplier performance, and predicting potential disruptions like natural disasters. Their AI-powered platform includes Risk Intelligence, which scans thousands of news posts to detect supply chain risks early, allowing proactive mitigation and continuous production flow. Read more here. | |

| 12. Performance Optimization | AI and cloud connectivity analyze live data from connected vehicles or fleets, identify patterns and send adjustments or updates to onboard systems to enhance performance, efficiency and user experience in real time. |

| Ford uses AI-driven connected vehicle analytics to optimize fleet performance. Their AI system collects real-time data from vehicles to improve fuel efficiency, predict maintenance needs, and update vehicle software remotely, enhancing overall vehicle health and customer experience. Read more here. |

Collectively, these innovations represent the tangible impact of AI on the automotive industry, which makes transportation intelligent, efficient, and environmentally responsible.

What are the Benefits of Using AI in the Automotive Industry for Companies and Customers?

As seen from the examples above, the use of AI in the automotive industry is creating measurable value across every layer of the automotive ecosystem. In fact, the benefits of AI in the automotive industry are beyond technological. They are also shaping how companies operate and how customers experience mobility.

The key benefits include:

1. Improved Safety and Reliability

One of the most critical benefits of AI in the automotive industry is its contribution to safety. With AI-driven sensors and analytics, vehicles can identify obstacles, detect driver fatigue, and predict potential collisions before they occur. Advanced Drive Assistance Systems (ADAS) further make driving safer and more responsive. Over time, these systems evolve and adapt to changing environments, reducing human error, and ensuring higher road reliability.

2. Operational Efficiency and Cost Optimization

With the use of AI, auto manufacturers are revolutionizing production and maintenance processes. AI streamlines manufacturing operations by automating quality inspections, optimizing inventory, and forecasting equipment failures. Predictive maintenance minimizes downtime and maximizes equipment lifespan. This directly translates to lower costs and greater operational agility.

3. Enhanced Customer Experience

The modern driver expects vehicles that are smart, intuitive, and personalized. AI enables manufacturers to meet those expectations by delivering customized in-car experiences. From adaptive infotainment systems to NLP assistants that predict serving and navigation, AI creates a seamless connection between the vehicle and the driver. The result? An enhanced journey, and improved satisfaction and loyalty.

4. Accelerated Innovation

The impact of AI in the automobile sector is also profound in research and development. AI driven design simulations and digital twins shorten R&D cycles and reduce prototype costs. Engineers use AI to test new materials, optimize aerodynamics, and enhance energy efficiency. All before production begins. This reduces the development cycles and ensures faster time to market.

5. Sustainability and Energy Management

Sustainability is a key priority for the future of AI in the automotive industry. And AI enables better energy management across both internal combustion and electric vehicles. With the development of AI apps and use of smart algorithms, customers can optimize EV battery performance, manage charging cycles, and reduce emissions via efficient routing.

6. Financial Impact and Long-Term Value

The most important impact of AI is its ability to drive financial growth and competitive differentiation. Manufacturers adopting AI enjoy reduced warranty claims, lower recall rates, and improved profit margins. The combination of efficiency, safety, and sustainability fosters brand trust and market leadership. Thus, the benefits of AI in the automotive industry translate to long-lasting business value, which offers resilience against industry disruptions.

While the benefits of using AI are many, there are also certain challenges that make adoption in the automotive sector complicated.

What are the Key Challenges in Adoption of AI in the Automotive Industry?

Implementing artificial intelligence is a complex process. When it has to be implemented in specialized sectors like automotive, it requires even more strategic planning, technical readiness, and cultural alignment to unlock its full benefits.

Here are some of those challenges of implementing AI in the automotive industry and how to tackle those:

1. High R&D Costs and Investment Requirements

Developing AI-powered systems demands significant investment in hardware, software, and talent. Building an AI software, which supports automation, vision processing, and predictive analytics requires long-term commitment.

To manage this, enterprises can adopt phased innovation and start small with pilot projects and collaborating through shared data ecosystems to lower costs. This ensures steady progress without overextending resources.

2. Integration with Legacy Systems

A major barrier in the use of AI in the automotive industry lies in integrating new AI capabilities with existing electronic control units (ECUs) and legacy IT infrastructure. This is because most manufacturing and design systems were not originally built for real-time AI processing.

To implement AI in the automotive industry, companies need to switch to modular architectures, middleware platforms, and API-based communication layers. This helps seamlessly bridge the gap between old and new systems.

Important: APIs and middleware may not suffice in all scenarios. That’s why, in some cases, it is best to replace the legacy system and go for AI modernization.

3. Data Security and Privacy Concerns

As vehicles and systems become more connected, the use of artificial intelligence in the automotive industry must stay aligned with data security and privacy standards. AI systems process vast amounts of sensitive data from sensors and telematics.

There should be proper provisions in place to protect this data from cyberattacks and unauthorized access. This is important for compliance as well as for user trust. The key is to ensure strong data management and security when building AI systems for the automotive industry.

4. Workforce Upskilling and Cultural Adoption

Embracing AI requires more than just a few new tools. It demands a shift in mindset. That’s why one of the most pressing challenges of using AI in the automotive industry is the need to retain employees.

Upskilling programs should thus be mandated for employees working across design, manufacturing, and after-sales services. These programs can equip teams with AI literacy, data interpretation skills, and digital collaboration skills. This speeds up AI adoption and helps extract greater value from AI.

5. Regulatory and Ethical Considerations

The application of AI in the automotive industry introduces regulatory and ethical dimensions. There are questions related to liability in autonomous driving, transparency in AI decision making, and data usage.

Mobility companies should thus prioritize safety compliance, explainable AI, and ethical governance when they scale AI adoption. This ensures regulatory approval and long-term trust.

Here is a quick summary of the challenges and how you can tackle them:

As we saw earlier, overcoming these challenges of AI in the automotive sector requires a balanced strategy where leaders combine technology with human expertise.

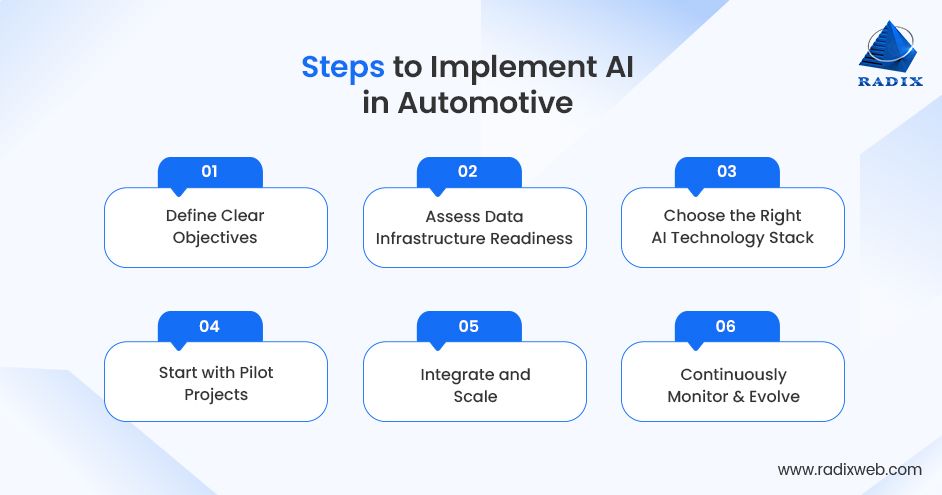

How to Implement AI in the Automotive Industry?

Ready to embrace AI? Well, success depends on execution rather than experimentation. And for that, you need a clear roadmap that aligns not just what is trending but your business goals and long-term vision. Here’s how to systematically implement AI in the automotive industry to ensure measurable outcomes and sustainable growth.

Step 1: Define Clear Objectives

The very first step is to establish SMART goals for AI integration. Whether the focus is on safety, sustainability, cost optimization, or innovation, clarity of purpose ensures effective resource allocation. Business leaders must identify the specific application of AI that aligns best with their priorities.

The first step in AI implementation planning is to establish SMART goals for AI integration.

Step 2: Assess Data Infrastructure Readiness

Data is the backbone of artificial intelligence in the automotive industry. Automakers must evaluate their ability to collect, store, and process data from multiple sources, like:

- Vehicle sensors

- Production lines and

- Customer telematics

Without a dependable data infrastructure, even the most advanced algorithms cannot deliver accurate insights. Establishing scalable data pipelines and cloud connectivity is therefore essential.

Step 3: Choose the Right AI Technology Stack

There are several AI programming languages, tools, and frameworks which can be used for implementation of AI in the automotive industry. Selecting the right combination is what determines the effectiveness of the AI automotive system. Also, you should discuss your compatibility with existing systems and compliance with cybersecurity standards during your initial AI consultations with vendors, in order to maximize performance and reliability.

Step 4: Start with Pilot Projects

Organizations should begin with smaller, controlled implementations before scaling. Examples include AI-based quality inspection, predictive maintenance, or intelligent logistics. These initial projects will help demonstrate the tangible impact of AI. It further allows teams to refine models, gather feedback, and build internal expertise. One the pilot/prototype is successful, it can be scaled across departments and business units.

Step 5: Integrate and Scale

After pilot validation, AI must be integrated into the broader operational ecosystem. The impact of AI in the automotive industry becomes evident when multiple systems, work in harmony with data-driven intelligence.

Step 6: Continuously Monitor and Evolve

AI implementation is not a one-time initiative. Continuous learning and optimization are vital to long-term success. By monitoring model performance and incorporating real-world data feedback, companies can ensure sustained accuracy and reliability. This ongoing evolution paves the way for a more adaptive and future-ready automotive enterprise.

A strategic, step-by-step approach allows companies to transform AI potential into practical value. When executed with discipline, the future of AI in the automotive becomes less about experimentation and more about measurable, scalable innovation that drives growth, safety, and sustainability.

Turning AI Insight into Real-World Automotive ImpactUnderstanding AI in the automotive industry is just the beginning. The true transformation happens when insights turn into implementation. That’s when data, algorithms, and strategy converge to create tangible outcomes.At Radixweb, we have deep expertise in artificial intelligence and the automotive industry. We’ve helped manufacturers, OEMs, and mobility startups translate AI potential into practical business value. We have partnered with leading enterprises to design intelligent software solutions that integrate seamlessly with production systems, connected vehicles, and supply chain networks.And these implementations aren’t limited to luxury brands or large-scale manufacturers. Mid-sized suppliers, mobility innovators, and EV startups are also hiring AI developers. In fact, AI is a democratizing force that allows automotive organizations, irrespective of their size, to compete in the dynamic mobility landscape.To explore how we can help you harness the full potential of AI, schedule a 30-minute strategic consultation with our tech architects. Together, we can turn innovation into impact and help you lead the next era of intelligent mobility.

Frequently Asked Questions

What role does AI play in automotive customer experience and after-sales services?

What’s next for AI innovation in automotive?

How can smaller automotive suppliers adopt AI technologies cost-effectively?

How does AI support automotive cybersecurity and data protection?

How can automakers measure ROI from AI initiatives?

Ready to brush up on something new? We've got more to read right this way.