Read More

Discover what’s next for AI in healthcare in 2026 - Get Access to the Full Report

ON THIS PAGE

- What is AI in Logistics?

- AI in Logistics: How It Has Evolved Over The Years?

- AI in Logistics: Popular Use Cases

- AI in Logistics: Benefits for Companies and Customers

- AI in Logistics: The Most Pressing Industry Challenges

- AI in Logistics: A Step-by-Step Implementation Roadmap

- Getting Started with AI in Logistics

ON THIS PAGE

- What is AI in Logistics?

- AI in Logistics: How It Has Evolved Over The Years?

- AI in Logistics: Popular Use Cases

- AI in Logistics: Benefits for Companies and Customers

- AI in Logistics: The Most Pressing Industry Challenges

- AI in Logistics: A Step-by-Step Implementation Roadmap

- Getting Started with AI in Logistics

Summary: Artificial Intelligence in the logistics industry is reshaping how global supply chains operate. From forecasting and route optimization to warehouse automation and last-mile delivery, AI in logistics helps enterprises improve visibility, reduce costs, and build smarter, more resilient, and customer-focused operations.

In the past few years, we’ve seen global supply chains undergo extraordinary pressure. Fuel costs are rising, market conditions are unpredictable and there is an unrelenting demand for faster delivery. All this has made logistics operations more complex now than ever before.

At Radixweb, we’ve worked closely with several logistics and transportation companies. In our engagement with these clients, we’ve observed that the use of technology in logistics is no longer an experiment. It has become the strategic foundation for businesses.

Today, artificial intelligence is the technology that is changing the logistics industry. And AI in logistics isn’t just about automation or cutting labor costs. It’s about building resilient, agile, and data-driven supply chains that can adapt to rapid market changes and customer expectations.

We’ve seen firsthand how AI allows enterprises to anticipate disruptions rather than react to them. The result? Faster deliveries, smarter resource allocation, and more sustainable operations.

So, for logistics leaders, the role of artificial intelligence in logistics has become impossible to ignore. In this blog, we explore what AI in logistics really means, how it delivers measurable business value, and how enterprises can practically integrate it into their operations.

What is AI in Logistics?

AI in logistics refers to the use of artificial intelligence technologies such as machine learning, predictive analytics, and computer vision to make logistics operations smarter and more efficient.

That is what helps companies automate planning, optimize routes, manage inventory, and analyze real-time data to improve decision-making. With artificial intelligence in logistics, businesses can predict disruptions instead of reacting to problems after they derail deliveries.

In simple terms, it is the digital brain of logistics, which turning raw data into actionable insights that help businesses move goods faster, safer, and at lower costs.

How has AI in Logistics Evolved Over the Years?

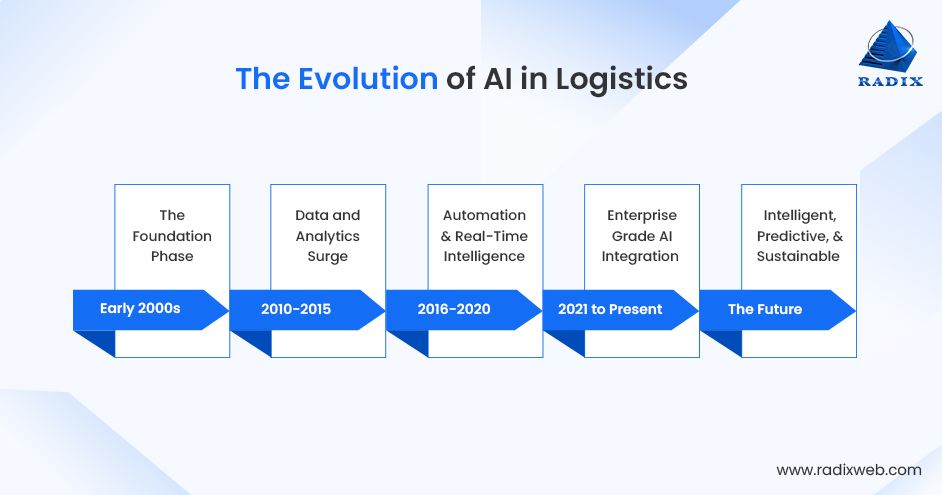

The use of AI in logistics and supply chain isn’t a futuristic concept as most people believe. The evolution has been consistent and practical, shaping the modern logistics ecosystem over the past two decades. Here’s how the evolution played out:

- Early 2000s: The Foundation Phase

- Introduction of basic automation in scheduling and dispatch systems

- Early use of rule-based algorithms for inventory and demand forecasting

- Focus was primarily on reducing manual errors and improving visibility

- 2010-2015: Data and Analytics Surge

- Emergence of big data and connected sensors across fleets and warehouses

- Use of predictive models for demand forecasting and route planning

- Shift from static reporting to real-time operational insights

- 2016-2020: Automation and Real-Time Intelligence

- Adoption of machine learning for fleet optimization and warehouse automation

- Robotics and computer vision systems streamline picking and sorting

- Real-time telemetry data enables proactive decision-making

- 2021 to Present: Enterprise-Grade AI Integration

- AI logistics solutions embedded in enterprise workflows and platforms

- Applications in dynamic load optimization, last-mile delivery, and risk management

- AI-driven supply chain software development will evolve from automation to adaptive, self-learning systems

- Future of AI in Logistics: Intelligent, Predictive, and Sustainable

- Widespread use of AI logistics software development for autonomous supply chains

- Integration of digital twin logistics with AI for scenario modeling and optimization

- Greater emphasis on sustainability through carbon-efficient route planning

- Collaboration between AI systems and humans to enable predictive, data-led decisions

Overall, AI in logistics is no longer experimental. There are many active AI in logistics examples, where it is driving modern supply chain towards agility, efficiency, and resilience.

Where is AI in Logistics Being Used in Real Life?

AI in logistics helps companies optimize operations, cut costs, and make faster, data-driven decisions. Here are some of the most practical and proven applications across the logistics landscape:

Predictive Demand Forecasting

Logistics providers across the globe are use AI‐driven logistics management systems today to analyze historical order patterns, market shifts and external factors (like weather, events) to predict where demand will surge or drop.

This ensures products are positioned right, inventory isn’t tied up unnecessarily, and supply chain agility is improved.

Smart Route & Fleet Optimization

Fleets leverage transport management software and AI-powered logistics to calculate the best delivery routes in real time by factoring in traffic congestion, fuel cost, vehicle availability, and delivery urgency. There have been many examples of carriers using dynamic routing systems, who have lowered idle time and fuel use significantly.

Warehouse Automation

In major fulfilment centers, robotics, computer-vision and AI control systems handle picking, sorting and packing. The use of AI in logistics software development enables warehouses to operate faster, with fewer errors, and adapt layouts or staffing in response to predicted workload.

Last-Mile Delivery Enhancements

With delivery costs often peaking in the last mile, companies implement AI in last-mile delivery tools that optimize driver assignments, reroute in-flight based on traffic, and provide precise ETAs to customers. This reduces costs and boosts overall satisfaction.

Risk Management & Supply Chain Resilience

Logistics networks spanning global geographies face more uncertainties than local-only operators. Use of AI in logistics allows companies to detect anomalies (supplier delays, port congestion, theft) and initiate contingency plans before issues escalate. This turns reactive logistics to proactive operations.

With that, it is clear how AI is transforming the logistics industry. Read on to know what tangible benefits they are driving.

What are the Benefits of AI in Logistics for Companies and Customers?

Artificial intelligence enables logistics operations that are not just faster but smarter, but adaptable, and also built for long-term efficiency. Here’s what businesses set to gain with AI:

Operational Efficiency and Agility

AI transforms logistics from reactive coordination to proactive optimization. Predictive maintenance tools anticipate vehicle or equipment failures before they occur. This reduces downtime and repair costs. Machine learning models optimize fleet utilization and warehouse throughput, cutting idle time and delays. Instead of adding manpower to solve bottlenecks, enterprises use AI logistics solutions to reallocate resources dynamically and achieve higher output with the same assets.

Enhanced Customer Experience

Today, transparency defines trust. This stands true for all industries and logistics is no different. By implementing AI in logistics and supply chain, companies can provide customers with accurate, real-time tracking, automated delivery notifications, and reliable ETAs. AI also helps detect potential delays early and suggest alternative options or time windows. This combination of visibility and responsiveness improves customer satisfaction, strengthens loyalty, and creates differentiation in crowded markets.

Strategic Scalability and Resilience

With artificial intelligence, logistics companies gain the agility to scale operations seamlessly while staying prepared for disruption. AI-driven simulations allow teams to test different routing, inventory, or supplier scenarios before making costly changes. During unexpected events, say port congestion or sudden demand spikes, AI systems can automatically rebalance supply chains to minimize impact. This turns logistics from a fixed network into a dynamic, self-adjusting system.

Sustainability and Green Operations

Environmental responsibility is no longer optional in supply chains. Through custom software development, businesses can plan eco-friendly routes, minimize fuel consumption, and maximize load efficiency. AI helps reduce empty runs and optimize delivery schedules, directly lowering emissions.

Financial Impact and Long-Term Value

The return on investment for AI in logistics is twofold:

- Immediate cost reduction

- Cumulative performance gains.

The immediate cost reduction with AI in logistics comes from saved fuel and labor costs, reduced waste, and minimum downtime. That way, companies see measurable savings within the first year. Over the long term, improved forecasting accuracy, better asset utilization, and stronger customer retention turn logistics into a consistent source of competitive and financial advantage.

In essence, AI logistics solutions help businesses achieve precision at scale, setting a benchmark for what intelligent logistics can deliver.

What are the Key Challenges Facing AI in Logistics?

The benefits of AI in logistics for enterprises of all sizes and scales are clear. However, the unique nature of the logistics industry brings about certain challenges in AI implementation.

Does that mean you should pause your plans for AI implementation. Absolutely, not. What you need to do is understand these challenges and build your strategy around them.

So here are the 5 most challenges of implementing AI in logistics and how forward-looking businesses can overcome them.

1. High Upfront Investment vs. Long-Term ROI

Impactful AI implementation for logistics requires upfront investment. This investment has to be in data infrastructure, cloud systems, and integration tools. At first glance, these costs seem daunting. However, instead of stepping back, the solution lies in approaching it as phased investment. To begin with, identify high impact areas. For example, you may want to start with AI-based route optimization systems which can show cost savings with the first year. Once you see early ROI, it becomes easier to fund further automation.

The key is to view AI not as a one-time expense but as a long-term enabler of sustainable growth.

2. Integration with Legacy Systems

Most businesses have legacy ERP and SCM systems in place. While useful, a lot of these older systems are not equipped to handle modern data analytics. This makes it hard, if not impossible, to integrate new AI capabilities into these environments.

To counter this, businesses need to adopt modular architectures and APIs. This helps connect AI layers to existing infrastructure. At Radixweb, we have also helped clients build middleware that allows data to flow seamlessly between old and new systems, which preserves investments while enabling innovation.

3. Data Availability and Accuracy

Your logistics AI models are only as good as the data they’re trained on. Incomplete, inconsistent, or outdated data can lead to poor predictions or incorrect insights.

To overcome this, you need to start by setting strong data governance policies. You may also use data cleansing tools before launching AI logistics app development initiatives. Based on our experience, setting up automated validation pipelines early on will help prevent most downstream data quality issues later on.

4. Workforce Readiness and Cultural Adoption

You will only benefit from the AI systems you build if it gets adopted in the right way. And that is never just a technical issue, but also about culture. More often than not, AI adoption instills a fear of job loss and change in established workflows among employees.

So, to ensure success in transportation and logistics projects, make sure the emphasis is on collaboration, not replacement. Training programs and transparent communication help teams see AI as an empowering tool. Positions AI as a helper that eliminates repetitive tasks and frees them for strategic, creative work is the key to making employees receptive to it.

Security and Compliance Challenges

With growing use of AI in logistics, protecting systems from cyber threats and staying compliant with industry regulations is a major concern. Logistics companies handle sensitive operational and customer data, making security lapses costly.

To manage this, you should:

- Strengthen cybersecurity measures

- Follow compliance standards

- Regularly monitor AI logistics solutions

This helps ensure safe and responsible use of technology across operations.

We've worked with several enterprises navigating these and helped them with realistic roadmaps for AI adoption. Read on to see how proper planning and partnerships can help tackle these challenges.

How to Implement AI in Logistics for Your Unique Business Needs?

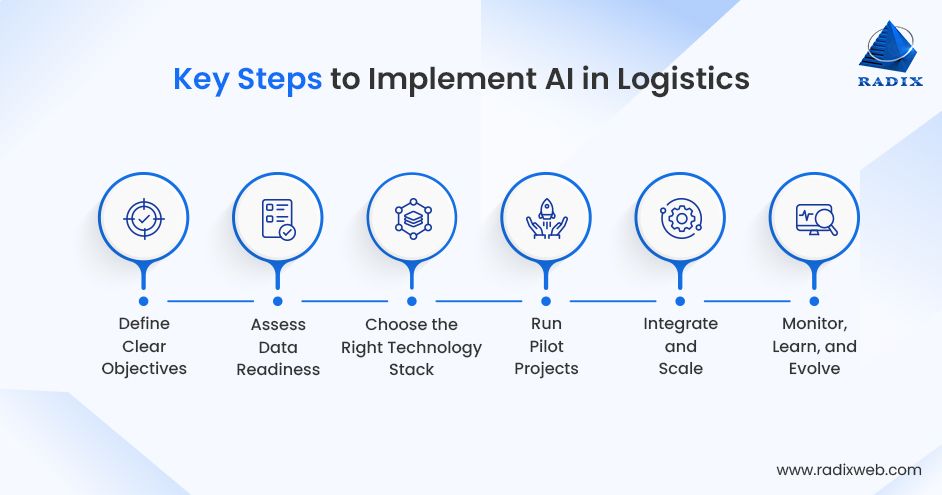

Implementing AI in logistics isn’t just about adopting new tech. It is about reshaping how your supply chain operates. Here's a structured AI adoption roadmap for logistics companies to get started:

Step 1: Define Clear Objectives

Every supply chain and logistics business is different. So, the first step to start implementing AI in logistics is to identify where AI can add the most value for you. It could be cost reduction, delivery speed, resource utilization or even sustainability initiatives. Then set clear, measurable goals to ensure that every initiative stays aligned with ROI targets.

Step 2: Assess Data Readiness

AI won't work without the right data in place. So, before you think about AI implementation, audit your existing data sources like fleet tracking systems and warehouse inventories. Make sure the data from across sources is consistent, accessible, and of good quality. The more dependable your data is, the better will your AI-driven logistics management systems be.

Step 3: Choose the Right Technology Stack

There are several tools, technologies, and AI programming languages that you can use to implement AI. But not all of them work the same way. For example, you may want to emphasis more on machine learning models, if your key objective is forecasting. But for building warehouse management software, computer vision would be more relevant. Based on your goals, work with your AI development partners to build the right AI tech stack.

Step 4: Run Pilot Projects

Instead of rolling out company-wide systemic changes with AI, use a module-wise approach. Deploy small AI solutions for logistics in a focused area first. Then measure outcomes, refine models, and build internal expertise before scaling across departments.

Step 5: Integrate and Scale

Once your AI pilots work well, integrate AI capabilities into your enterprise workflows. But remember to scale them strategically and while ensuring proper communication between systems, processes, and people. This will help you inch towards a fully connected logistics ecosystem.

Step 6: Monitor, Learn, and Evolve

Artificial intelligence is a rapidly evolving technology. This means you also need to continuously improve your systems to stay ahead of the curve. Make sure you regularly analyze performance data, gather feedback from ops teams, and update the models. This helps keep up with both evolving logistics dynamics and AI market conditions.

With this structured approach you can turn AI strategies into impactful solutions that drive your business forward.

Turning AI Insight into Real-World Logistics ImpactUnderstanding AI in logistics is the first step. The actual transformation will begin when you start implementing it in a structured and purpose-driven way.At Radixweb, we’ve helped several organizations design and deploy AI logistics solutions. With these solutions, we’ve helped them simplify complex workflows, reduce operational cost leakage, and deliver measurable business value.Our team of AI developers brings deep domain expertise in supply chain dynamics and AI logistics software development. This techno-functional expert helps our clients move from strategy to execution, with full confidence.Want to get started with artificial intelligence in the logistics industry? Schedule a 1-on-1 strategy session with our experts to see what’s possible The age of AI in logistics and supply chain is here. Let Radixweb help you lead that change.

FAQs

How much does it cost to build an AI-powered logistics platform?

How does AI help lower last-mile delivery costs?

What is the ROI of implementing AI in logistics operations?

How long does it take to implement an AI system in logistics?

Is AI suitable for small or mid-sized logistics companies?

Can AI systems work with older logistics software?

Ready to brush up on something new? We've got more to read right this way.